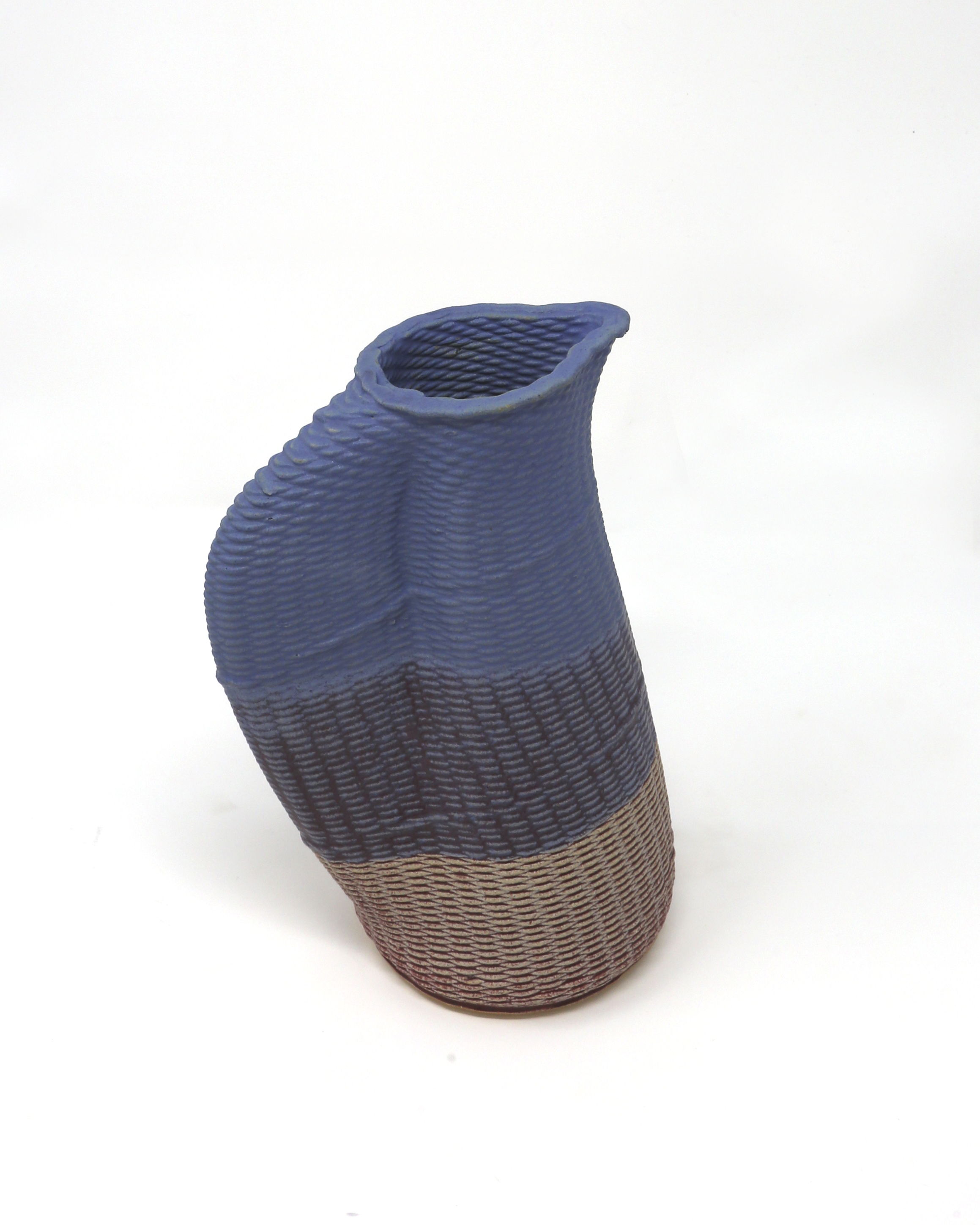

PITCHER

YEAR: 2023

STUDIO: Iowa State University: Ceramics and Computation and Construction Lab

MATERIAL: Ceramic, food-safe glaze

QUALITIES: 3D-printed

DESCRIPTION︎︎︎

7.5”h x 4.75”

Combining 3D-printed forms and analog fabrication by YanJiu Bai, under the direction of Shelby Doyle, each piece is surfaced with glazes created by Ingrid Lilligren. Fired to Cone 6 in an electric kiln, these represent our collaboration that brings cutting-edge technology together with sustainable ceramic practices. Each piece is entirely functional and food safe.

This work is a result of a six-year partnership between the ISU Ceramics Studio and ISU Computation & Construction Lab. Both are housed in the Iowa State University College of Design. One of the most comprehensive design colleges in the country, it is home to seven departments, fostering opportunities for unique multidisciplinary collaborations.

The ISU Computation & Construction is an initiative of the Department of Architecture and is home to $1 million in digital fabrication and robotics equipment that support cutting edge teaching and research. The ISU Ceramics studio is housed in the Department of Art and Visual Culture with a focus on sustainable practices in ceramics.

The collaboration began with the development of SEKI, a collection of eighty unique vases designed for President Wendy Wintersteen’s installation in 2018. Each vase represents the integration of custom-made glazes with computational designs and clay 3D printing. An important innovation of this project was the use of Cone 6 electric kiln glazes that rely upon Iowa’s wind energy rather than gas. The palette of glaze colors was inspired by the University Museums’ Iowa College Pottery collection, thereby connecting advances in ceramic technology to its history at Iowa State.

In 2021 ISU College of Design became part of a team exploring 3D printing rural affordable housing. The cups and pitchers sold here are the result of imagining 3D printed dinnerware for a 3D printed house. The techniques demonstrated here were developed during YanJiu Bai’s Master of Science thesis Designing Access to Clay 3D Printing for Ceramic Artists.

All proceeds from the sale of the cups and pitchers will be donated to the ISU Ceramics Studio to support future collaborations and student work.

CHANDELLE

YEAR: 2023

STUDIO: Labo-d’

MATERIAL: Ceramic

QUALITIES: Shiny, Aggregated

DESCRIPTION︎︎︎

5”h x 4.5” x 3.5”

Chandelle is a ceramic work made of glazed Buffalo wallow clay consisting of a balancing candle-holding cylinder and a truncated conical volume. The forms intersect to create a decorative object that plays on the theme of reflection and layers; a two-sided object that can be used as a candle holder on one side, and a receptacle (for a bloom) on the other. Chandelle is handmade and therefore each item is slightly different; candle not included.

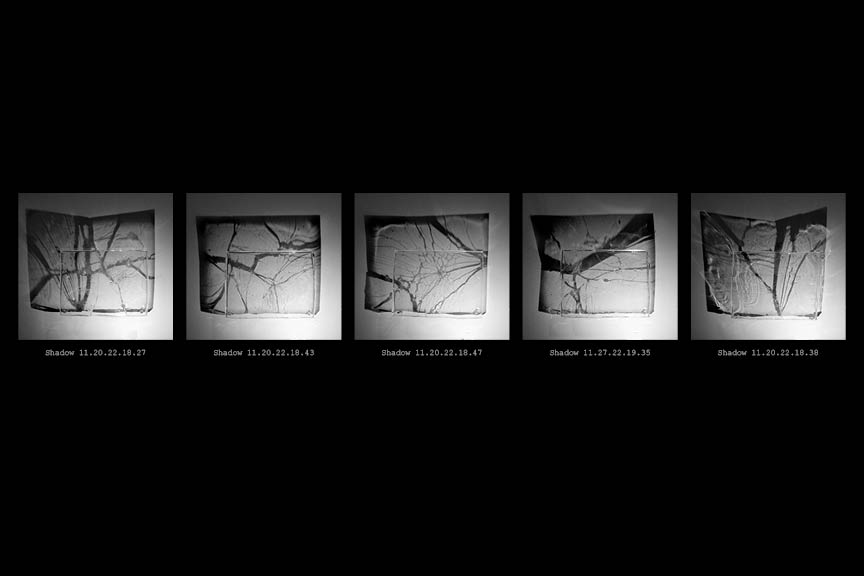

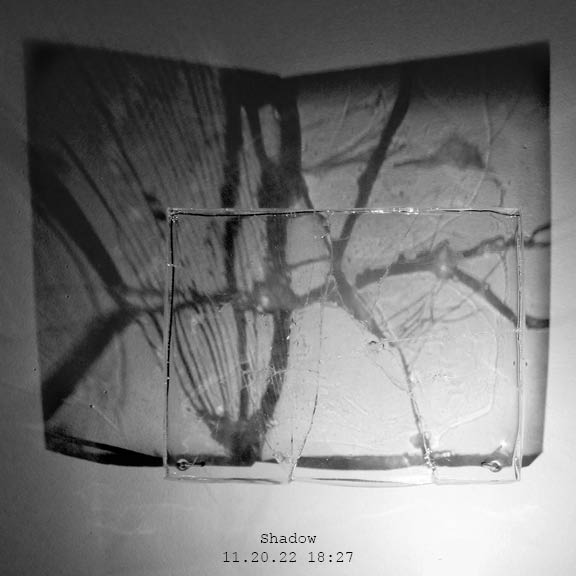

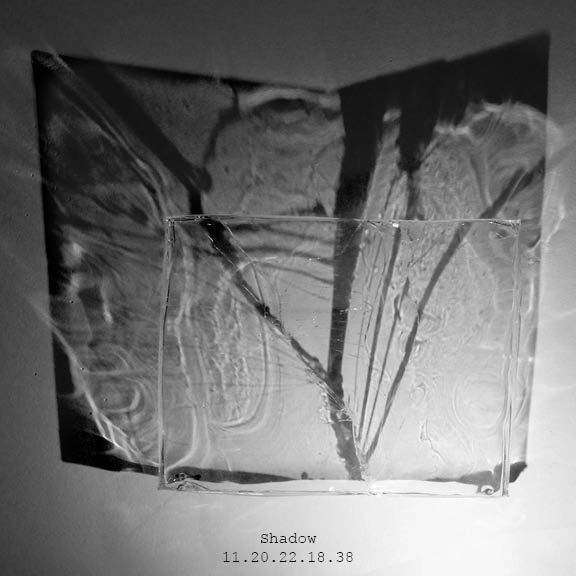

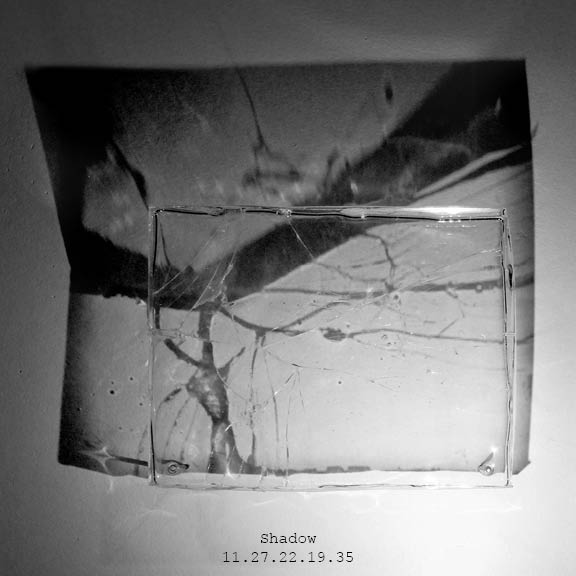

SHADOW LIGHT

YEAR: 2023

STUDIO: obj

MATERIAL: Glass, resin, stainless steel

QUALITIES: Distorting, Interactive

DESCRIPTION︎︎︎

6.5”h x 5.25” x 3”

A series of broken shadows. A floating piece of shattered glass frozen in time expresses itself on the wall under the luminescence of a cantilevered pin light. Produced in series, each piece is named as the moment it was born.

Shattered Glass in Resin with Stainless Steel Rods

3D-Printed Light with Micro 12V LED

Power cord

CUP

YEAR: 2023

STUDIO: Iowa State University: Ceramics and Computation and Construction Lab

MATERIAL: Ceramic, food-safe glaze

QUALITIES: 3D-printed

DESCRIPTION︎︎︎

4”h x 3.375”

Combining 3D-printed forms and analog fabrication by YanJiu Bai, under the direction of Shelby Doyle, each piece is surfaced with glazes created by Ingrid Lilligren. Fired to Cone 6 in an electric kiln, these represent our collaboration that brings cutting-edge technology together with sustainable ceramic practices. Each piece is entirely functional and food safe.

This work is a result of a six-year partnership between the ISU Ceramics Studio and ISU Computation & Construction Lab. Both are housed in the Iowa State University College of Design. One of the most comprehensive design colleges in the country, it is home to seven departments, fostering opportunities for unique multidisciplinary collaborations.

The ISU Computation & Construction is an initiative of the Department of Architecture and is home to $1 million in digital fabrication and robotics equipment that support cutting edge teaching and research. The ISU Ceramics studio is housed in the Department of Art and Visual Culture with a focus on sustainable practices in ceramics.

The collaboration began with the development of SEKI, a collection of eighty unique vases designed for President Wendy Wintersteen’s installation in 2018. Each vase represents the integration of custom-made glazes with computational designs and clay 3D printing. An important innovation of this project was the use of Cone 6 electric kiln glazes that rely upon Iowa’s wind energy rather than gas. The palette of glaze colors was inspired by the University Museums’ Iowa College Pottery collection, thereby connecting advances in ceramic technology to its history at Iowa State.

In 2021 ISU College of Design became part of a team exploring 3D printing rural affordable housing. The cups and pitchers sold here are the result of imagining 3D printed dinnerware for a 3D printed house. The techniques demonstrated here were developed during YanJiu Bai’s Master of Science thesis Designing Access to Clay 3D Printing for Ceramic Artists.

All proceeds from the sale of the cups and pitchers will be donated to the ISU Ceramics Studio to support future collaborations and student work.

MUG

YEAR: 2023

STUDIO: Iowa State University: Ceramics and Computation and Construction Lab

MATERIAL: Ceramic, food-safe glaze

QUALITIES: 3D-printed

DESCRIPTION︎︎︎

4” x 3.375”

Combining 3D-printed forms and analog fabrication by YanJiu Bai, under the direction of Shelby Doyle, each piece is surfaced with glazes created by Ingrid Lilligren. Fired to Cone 6 in an electric kiln, these represent our collaboration that brings cutting-edge technology together with sustainable ceramic practices. Each piece is entirely functional and food safe.

This work is a result of a six-year partnership between the ISU Ceramics Studio and ISU Computation & Construction Lab. Both are housed in the Iowa State University College of Design. One of the most comprehensive design colleges in the country, it is home to seven departments, fostering opportunities for unique multidisciplinary collaborations.

The ISU Computation & Construction is an initiative of the Department of Architecture and is home to $1 million in digital fabrication and robotics equipment that support cutting edge teaching and research. The ISU Ceramics studio is housed in the Department of Art and Visual Culture with a focus on sustainable practices in ceramics.

The collaboration began with the development of SEKI, a collection of eighty unique vases designed for President Wendy Wintersteen’s installation in 2018. Each vase represents the integration of custom-made glazes with computational designs and clay 3D printing. An important innovation of this project was the use of Cone 6 electric kiln glazes that rely upon Iowa’s wind energy rather than gas. The palette of glaze colors was inspired by the University Museums’ Iowa College Pottery collection, thereby connecting advances in ceramic technology to its history at Iowa State.

In 2021 ISU College of Design became part of a team exploring 3D printing rural affordable housing. The cups and pitchers sold here are the result of imagining 3D printed dinnerware for a 3D printed house. The techniques demonstrated here were developed during YanJiu Bai’s Master of Science thesis Designing Access to Clay 3D Printing for Ceramic Artists.

All proceeds from the sale of the cups and pitchers will be donated to the ISU Ceramics Studio to support future collaborations and student work.